Flexible Electronics

Flexible Electronics

July 1, 2024 | By beespenser Flexible Electronics Home Products BS-One Conductive Inks Support Contact Us Learn Blog Industries In the News FAQs Pre-Order NOW! Home Products BS-One Conductive Inks Support Contact Us Learn Blog Industries In the News FAQs Pre-Order NOW! Flexible Electronics The Technology of the Future Flex electronics, also known as flexible […]

Beespenser at the 1st EELISA Conference organized by EELISA

At Beespenser, we are very excited to be part of the EELISA European University Association! One of our founders, Yaren Özdemir, attended the 1st EELISA Conference held in Bucharest, Romania. EELISA is an association established to promote collaboration and innovative projects between universities in Europe. At this important event, we express our deep gratitude to […]

Beespesner Wins First Prize at E‑Hub Üsküdar DemoDay Event!

We are thrilled to announce our triumph at the DemoDay event hosted under the E‑Hub Üsküdar Project. It was an incredible gathering where pioneering minds in the entrepreneurial sphere converged, showcasing the unique and innovative ventures driving the future’s transformative force. 🚀 As a mission-driven initiative aiming to elevate the innovation and entrepreneurship ecosystem, this […]

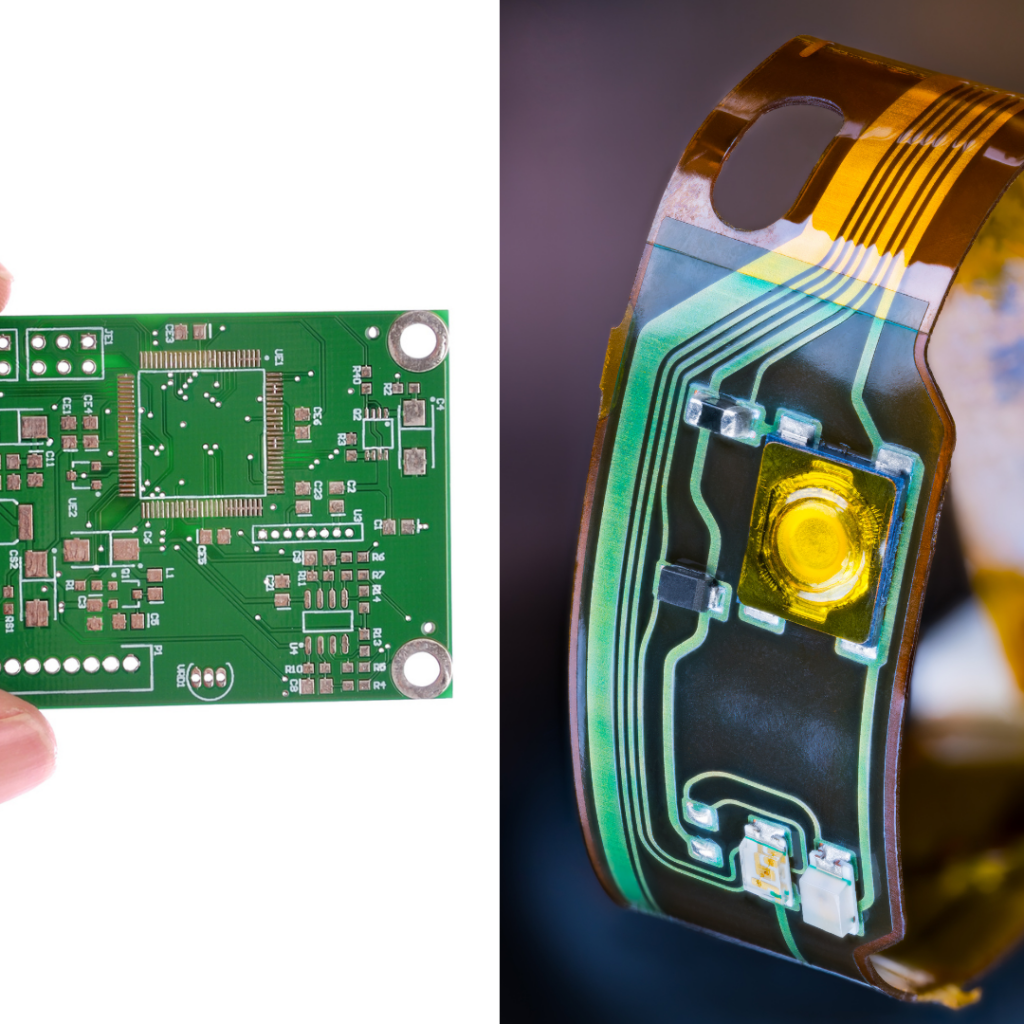

Flexible Substrates: The Foundation of Flex Electronics

Flexible substrates form the base on which electronic circuits are built. Commonly used substrates include plastic films, polyimide, and thin glass. Their flexibility allows devices to bend and stretch, enabling innovative form factors that were previously unimaginable.

Organic Semiconductors: The Heart of Flex Electronics

Organic semiconductors are essential for creating the active components of flexible electronics, such as transistors and diodes. These materials can be processed at low temperatures, making them ideal for flexible substrates. This combination allows for the production of lightweight, flexible electronic devices with complex functionalities.

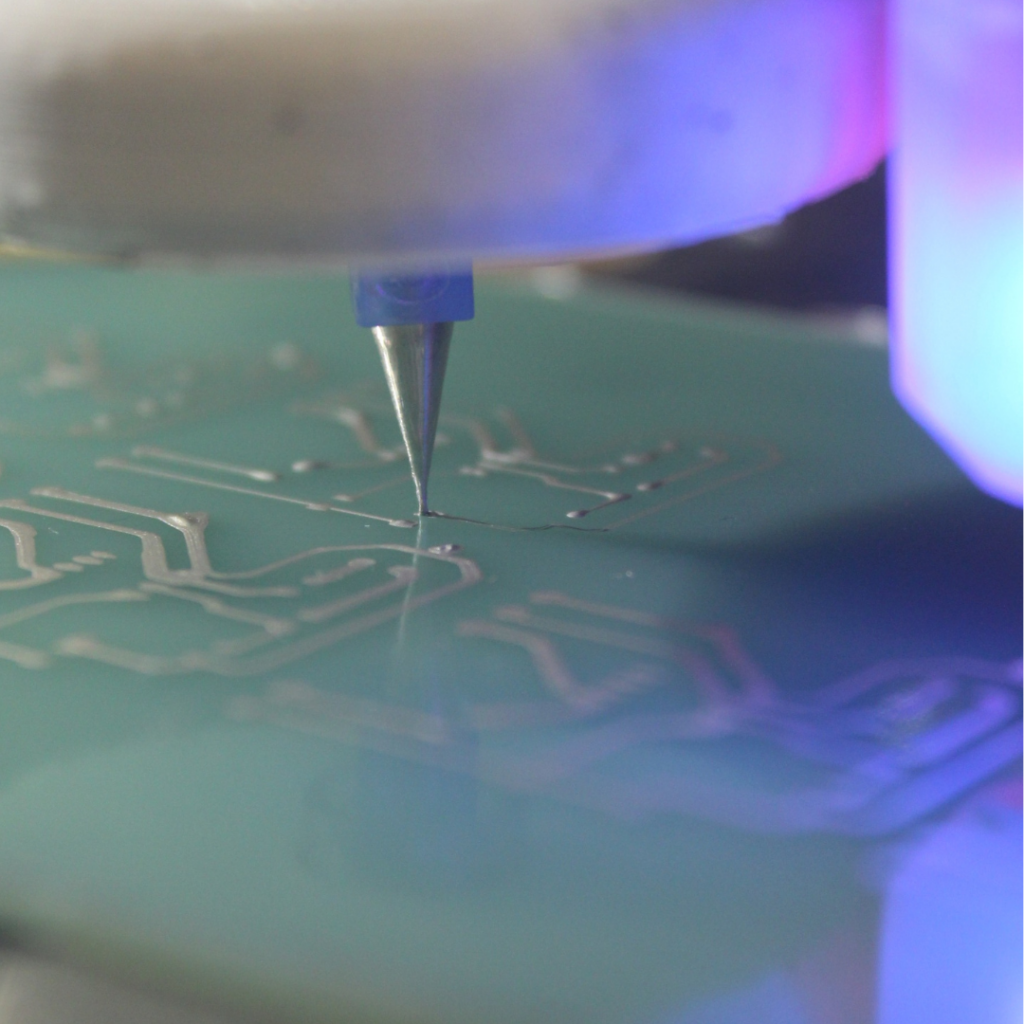

Conductive Inks: Printing the Future

Conductive inks, containing materials like silver, copper, or carbon nanotubes, are printed onto flexible substrates to form electronic circuits. This printing process is similar to traditional inkjet or screen printing, making it cost-effective for large-scale production and ideal for creating complex circuits on flexible surfaces.

Applications of Flexible Electronics

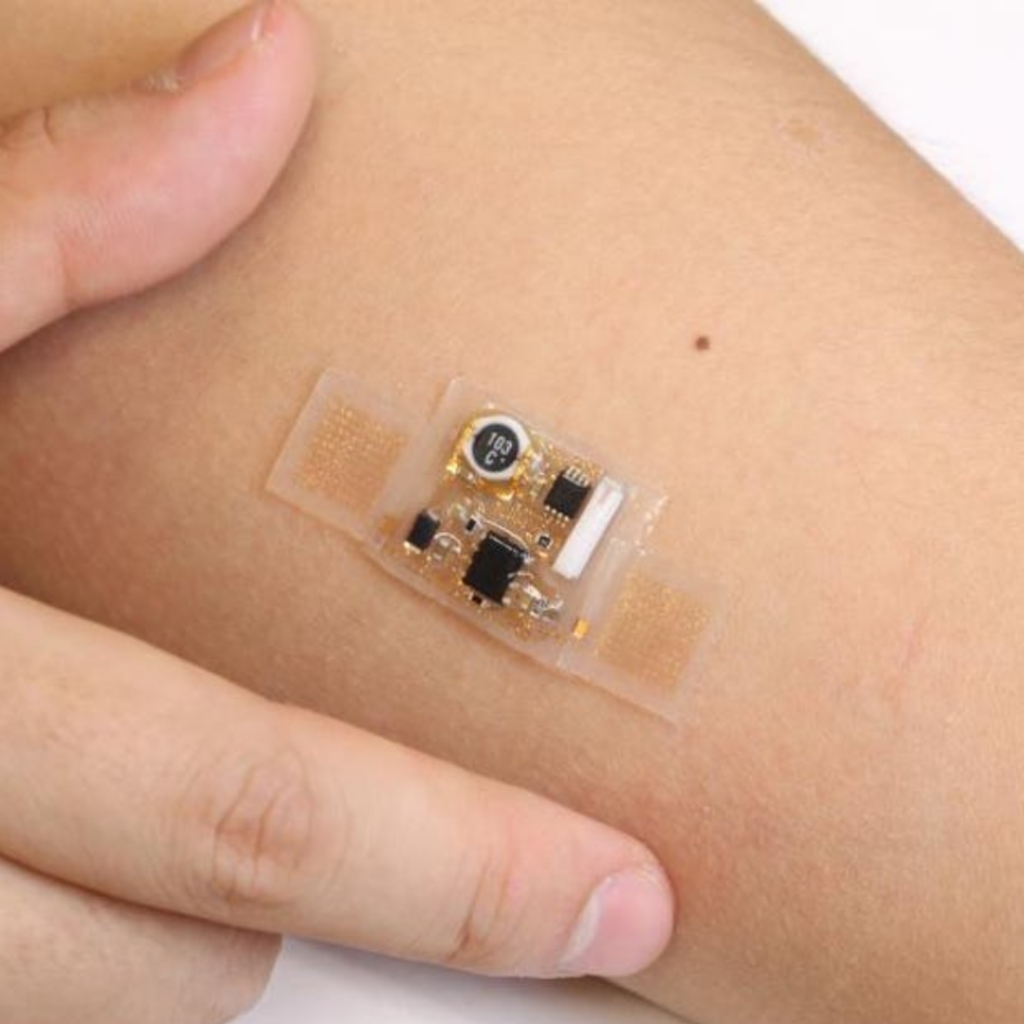

Wearable Devices

Flex electronics are at the forefront of wearable technology. Devices like smartwatches, fitness trackers, and health monitoring patches benefit immensely from flexibility, as it allows these devices to conform to the body’s shape and movements, offering increased comfort and enhanced functionality.

Healthcare

In healthcare, flexible electronics are enabling the creation of advanced diagnostic and therapeutic devices. For instance, flexible sensors can monitor vital signs, wound healing, or even drug delivery, providing non-invasive and continuous monitoring options.

Consumer Electronics

The consumer electronics industry is seeing a surge in innovation with flex electronics, leading to the development of products like foldable smartphones, rollable displays, and lightweight, flexible solar panels. These innovations are not only enhancing user experiences but also introducing new functionalities.

Industrial Applications

In industrial settings, flexible sensors and circuits are being integrated into smart textiles, robotic skins, and structural health monitoring systems. These applications enhance efficiency, safety, and real-time data collection across various sectors.

Advantages of Flexible Electronics

Design Freedom

Flex electronics offer unprecedented design flexibility, allowing for innovative shapes and configurations that traditional rigid electronics cannot achieve. This opens up new possibilities for product design and user interaction.

Durability

The ability to withstand bending, folding, and stretching makes flex electronics more durable in many applications. This resilience can lead to longer-lasting devices and reduced maintenance costs.

Lightweight and Thin

Flexible electronic devices are typically lighter and thinner than their rigid counterparts, making them more portable and easier to integrate into various environments and products.

Cost-Effective Production

Techniques like roll-to-roll printing and low-temperature processing enable the mass production of flexible electronics at lower costs compared to traditional silicon-based electronics.

Challenges and Future Directions

Despite its promising potential, flex electronics still face several challenges. The durability of flexible materials, especially under repeated mechanical stress, requires further improvement. Additionally, the performance of flexible components, such as transistors and batteries, must match or exceed that of their rigid counterparts to gain broader adoption. Ongoing research is focused on enhancing material properties, refining manufacturing techniques, and expanding the range of applications. Advances in nanotechnology, materials science, and printing technologies are expected to drive significant progress in the field.

Flex electronics represent a transformative leap in technology, offering a wide range of benefits and applications across various industries. As the technology continues to evolve, it holds the promise of creating more innovative, durable, and versatile electronic devices, shaping the future of how we interact with and use technology.

Copyright © 2024 Beespenser Teknoloji Anonim Şirketi All rights reserved.