Cost-Effectiveness

Say goodbye to high shipping costs and minimum order requirements.

Traditional circuit prototyping often involves large upfront costs, minimum order requirements, and expensive shipping fees from overseas manufacturers. Beespenser eliminates these barriers, allowing you to create prototypes in-house at a fraction of the cost.

With no hidden fees and the ability to produce only what you need, Beespenser is the ultimate solution for startups, small businesses, and R&D labs looking to maximize their budget.

Sustainability

Eco-friendly additive manufacturing technology.

At Beespenser, we believe innovation shouldn’t come at the cost of the planet. Our additive manufacturing process minimizes material waste and reduces the carbon footprint compared to traditional methods.

By using advanced conductive inks and avoiding harmful chemicals, we ensure that every prototype you produce contributes to a greener, more sustainable future. Join us in making electronics not only smarter but also cleaner.

Flexibility

Compatible with both rigid and flexible surfaces.

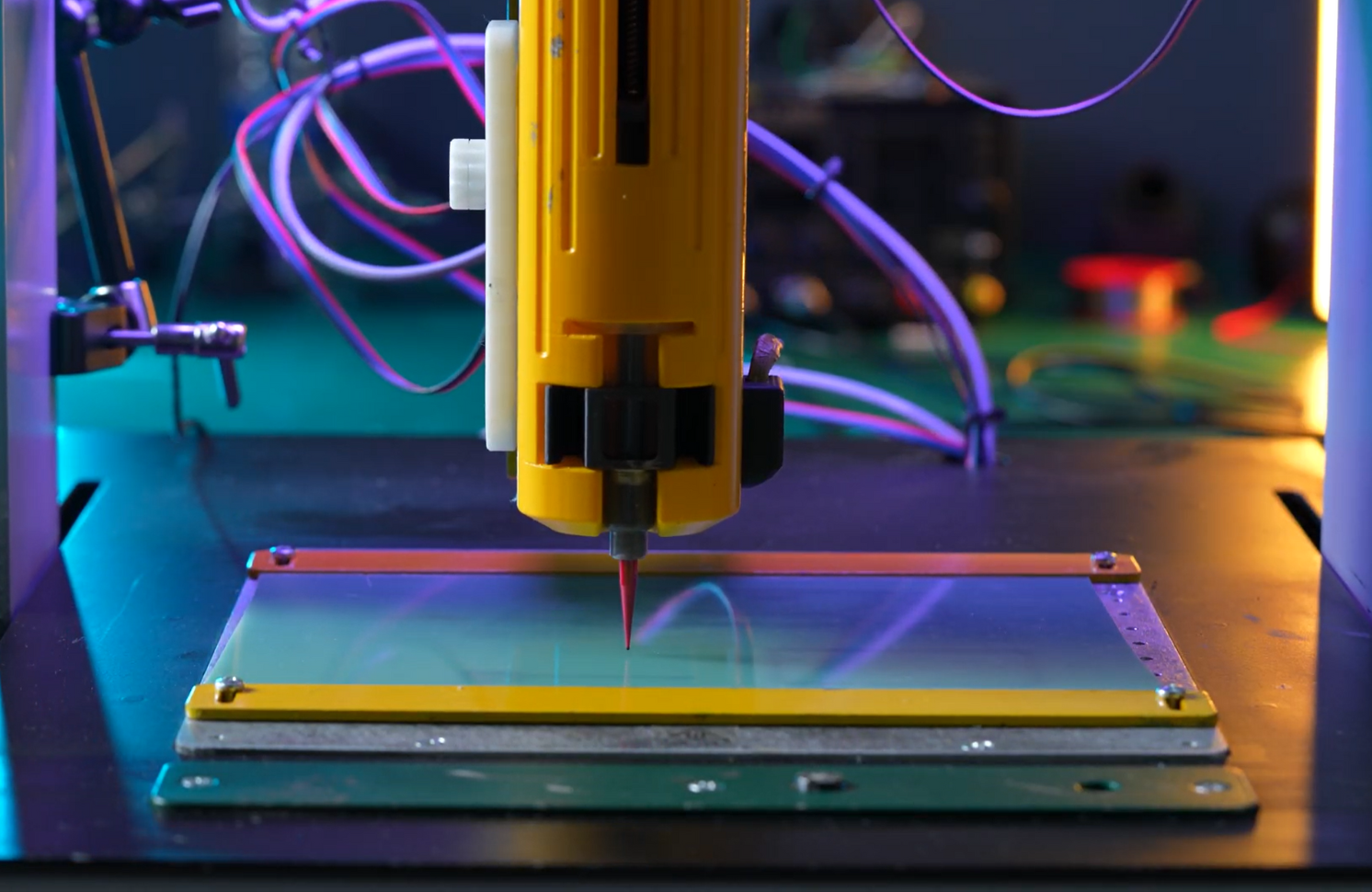

Modern electronics demand adaptability. Beespenser’s innovative technology enables circuit production on both rigid and flexible materials, making it ideal for applications like wearables, healthcare devices, and advanced IoT solutions.

Our system uses high-precision conductive ink printing, ensuring durability and reliability on any surface. No matter your project’s needs, Beespenser gives you the flexibility to innovate without limits.

Speed & Efficiency

Produce prototypes in under an hour.

Traditional prototyping can be time-consuming and costly, often requiring external manufacturing and long wait times. Beespenser revolutionizes this process by enabling you to design, print, and finalize your circuit prototypes in as little as 15 minutes to 1 hour, depending on complexity.

Our advanced additive manufacturing system ensures rapid iteration, allowing you to identify and fix design flaws quickly. Whether you’re an engineer, a startup, or a researcher, Beespenser’s speed helps you bring your ideas to life faster than ever.

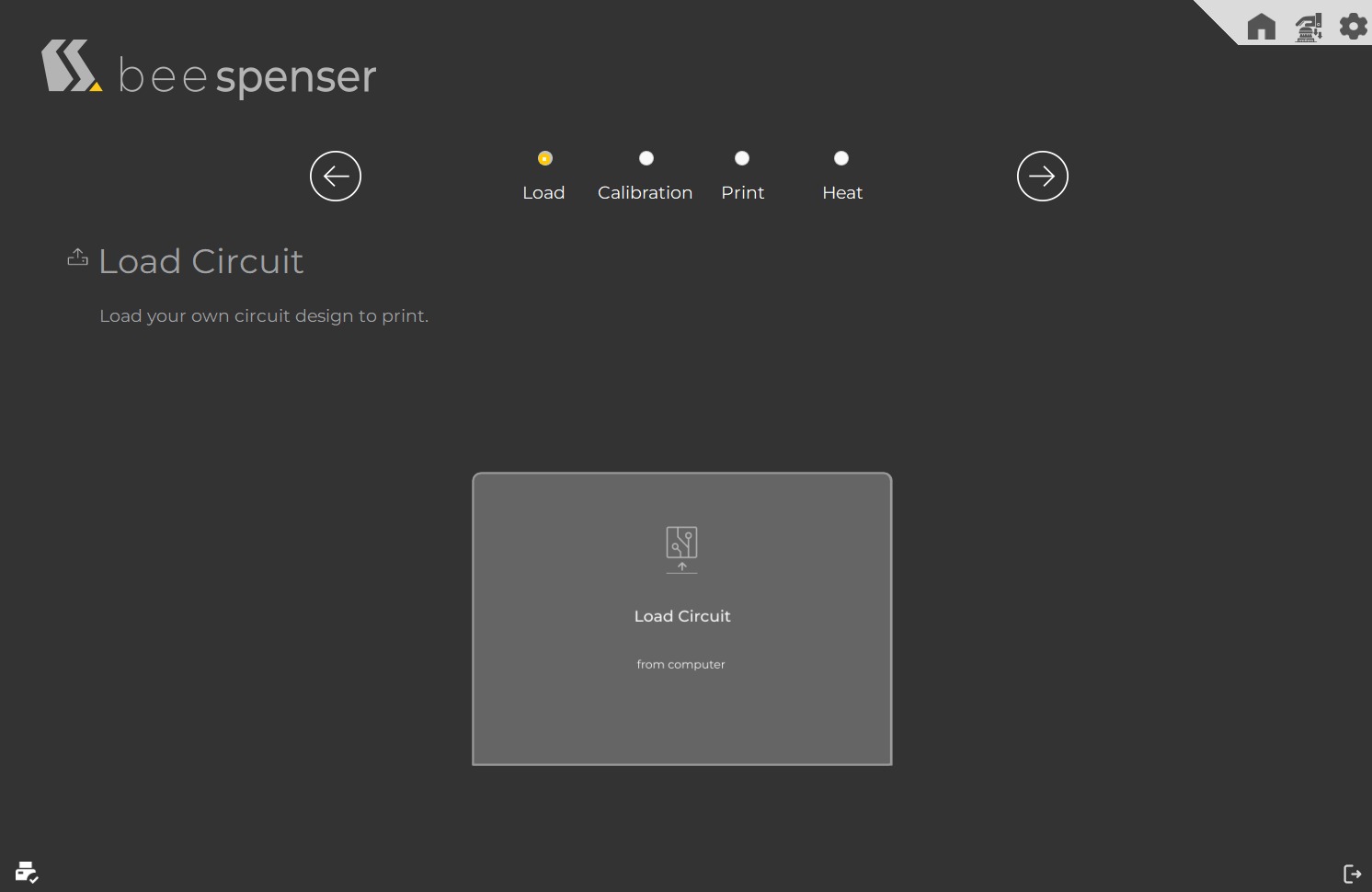

How It Works

Prototyping Made Easy in 3 Steps:

Upload your design.

Watch Beespenser bring it to life.

Get your circuit prototype ready for testing.

Designed for Innovators Like You

Who Is Beespenser For?

Startups and Small Tech Firms

Speed and flexibility are critical for startups. Beespenser empowers small teams to prototype and iterate faster, reducing costs and time-to-market. Build your ideas, refine your designs, and stay ahead in the competitive tech world.

R&D Labs in Universities

Beespenser is an essential tool for academic research labs. From exploring new materials to developing cutting-edge electronics, our device supports innovation at every step. Simplify teaching and prototyping processes for students and researchers alike.

Engineers Creating Next-Gen Electronics

Engineers pushing the boundaries of technology need tools that adapt to their vision. Beespenser enables the creation of flexible and complex circuits for wearables, healthcare devices, and beyond.

Start Prototyping Smarter Today!

Schedule a Demo: Experience Beespenser in action! Book a personalized demo session with our experts to see how our technology can revolutionize your prototyping process. It’s quick, easy, and tailored to your needs.

Pre-order Now: Be among the first to access the future of prototyping. Reserve your Beespenser device today and unlock exclusive early-bird benefits. Don’t wait—take the next step towards smarter circuit design!

See How Beespenser is Transforming

Prototyping Across Industries

From startups to global enterprises, our customers are revolutionizing their industries with Beespenser’s innovative technology. Explore real-world stories of how they overcame challenges, accelerated development, and embraced sustainable practices.

Eco-Friendly Prototyping at Scale

- Challenge: Their existing manufacturing process generated excessive waste, conflicting with their sustainability goals.

- Solution: Beespenser’s additive manufacturing reduced waste by 80% and eliminated harmful chemicals.

- Result: GreenCircuits met their sustainability targets while maintaining high-quality standards.

Precision and Biocompatibility for Life-Saving Devices

- Challenge: Prototyping compact, biocompatible circuits for a new healthcare device was costly and time-consuming.

- Solution: Using Beespenser’s high-resolution printing and advanced ink technology, SmartMed developed functional prototypes quickly and safely.

- Result: The device was ready for clinical trials 2 months ahead of schedule, cutting costs by 30%.

Prototyping Curved Circuits Made Simple

- Challenge: Traditional methods couldn’t meet the flexibility requirements of their wearable sensors.

- Solution: Beespenser’s stretchable PCB technology allowed FutureWear to produce high-quality prototypes for curved surfaces.

- Result: The company created functional prototypes 60% faster, speeding up product testing and market entry.

From Idea to Prototype in Hours

- Challenge: InnovateTech faced delays in prototyping IoT circuits due to long lead times and outsourcing costs.

- Solution: With Beespenser, they brought prototyping in-house, reducing production time by 95%. This allowed them to launch their IoT product 3 months ahead of schedule.

- Result: InnovateTech saved $20,000 in prototyping costs while improving design iteration speed.

Inspired by These Stories? Join the Revolution in Prototyping!

Frequently Asked Questions

You can find the questions you are curious about here. Please get in touch if you have any further questions.

Beespenser is a smart dispensing system designed to provide precise control and automated distribution of conductive inks, adhesives, and other materials used in printed electronics and PCB production.

PCB stands for Printed Circuit Board. It is a flat board that electrically connects and mechanically supports electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate.

Printed electronics refers to the process of creating electronic devices and circuits by printing conductive materials, such as conductive inks, onto flexible or rigid substrates like paper, plastic, or glass.

Conductive inks are specialized inks that contain conductive materials, such as silver, copper, or carbon, allowing them to conduct electricity. These inks are widely used in printed electronics, flexible circuits, and other advanced manufacturing applications.

Yes, you can print with your own ink by using the advanced calibration feature in our interface. As long as you know the viscosity of your ink, you can easily adjust the settings to achieve optimal results.

What Our Users Say

Trusted by researchers, engineers, and startups worldwide.

Sustainable and innovative manufacturing technologies are shaping the industry of the future. With its eco-friendly and recyclable PCB production, Beespenser not only reduces the carbon footprint but also accelerates electronic manufacturing processes, creating a major transformation.

At WearTechClub, we use high-performance electronic components in the field of wearable technology and smart sportswear. We’ve implemented Beespenser solutions in our product development processes, and thanks to its rapid prototyping capabilities, our R&D cycles have significantly accelerated. The flexibility and sustainability provided by additive manufacturing technology are among the key factors shaping the future of electronics production.

Beespenser is not just a supplier for technology-focused brands, but a solution partner that makes manufacturing processes more efficient, environmentally friendly, and innovative.

Beespenser saved us weeks of prototyping time! We went from concept to testing in hours, not days. It’s a game-changer for startups like ours.

The ability to prototype flexible circuits directly in our lab has opened up new possibilities for wearable tech development. Beespenser is simply unmatched.

What stood out the most was the sustainability aspect. We’re creating better prototypes while being environmentally conscious. Truly the future of electronics!

I was blown away by how easy it was to use. Upload your design, and Beespenser does the rest. It’s like having a miniature factory at your desk!