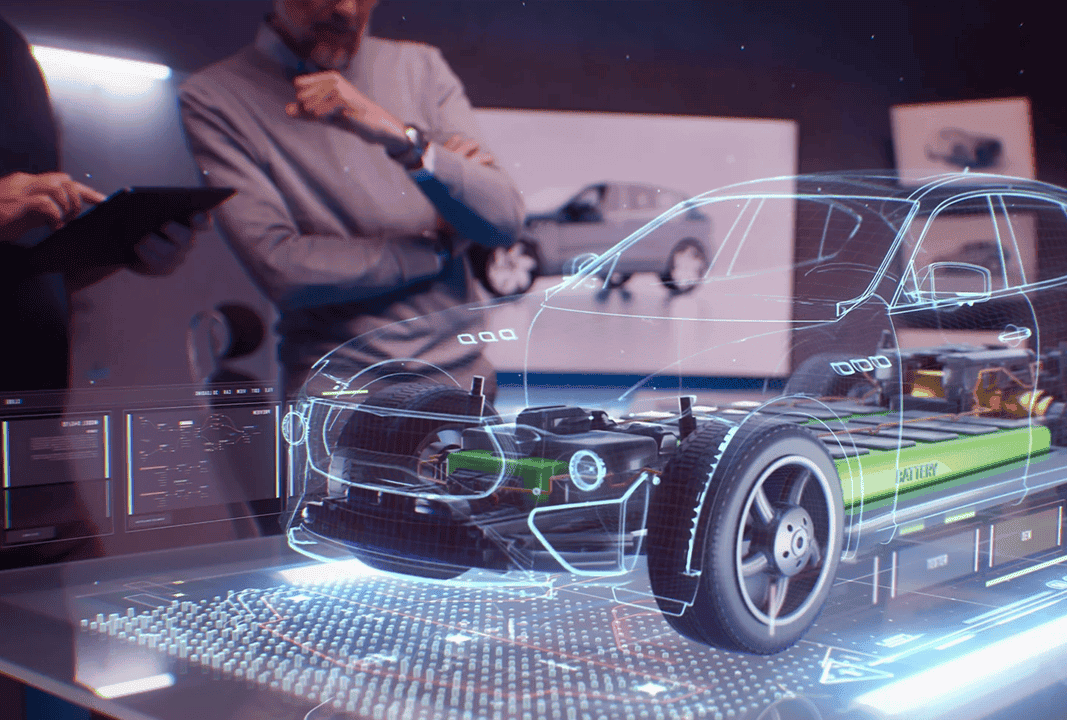

The automotive industry is undergoing a significant transformation, driven by advancements in technology that prioritize safety, performance, and user experience. Central to this evolution is the integration of smart systems and electronic sensors into vehicle components. Dispensing technology plays a pivotal role in this process, offering precision and reliability in manufacturing. A prime example of its application is found in automotive glass, particularly rear windows, where functionality meets innovative design.

The Black Stripes on Automotive Glass: More Than Meets the Eye

The black stripes and dots visible on automotive glass, especially on rear windows, serve a variety of critical functions beyond aesthetics. These features enhance the glass’s resistance to sunlight, helping to regulate the vehicle’s interior temperature. Additionally, they improve the structural integrity of the glass, reducing the risk of cracking or deformation during thermal processing. An equally vital role is their contribution to defrosting and demisting systems, which ensure clear visibility by quickly removing frost or fog.

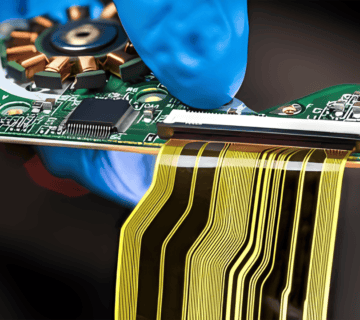

These functional stripes are applied with exceptional precision using advanced dispensing technology. Specialized inks and conductive materials are carefully dispensed onto designated areas of the glass, ensuring uniformity in production and durability of the final product. This precise application underscores the importance of dispensing devices in delivering reliable and high-performing automotive solutions.

Heating Stripes and Dispensing Technology

In many cases, the black stripes on automotive glass also serve as heating elements. Made from conductive materials, these stripes generate heat through electrical currents, aiding in the defrosting and demisting processes. Dispensing technology offers numerous benefits in the application of these heating elements, including unmatched precision and consistency. It ensures that stripes are applied with uniform thickness and length, meeting stringent performance standards.

The versatility of dispensing technology supports the use of various specialized inks, such as UV-resistant, conductive, or thermoformable inks, tailored to diverse automotive requirements. Additionally, it accelerates large-scale production processes, enhancing both efficiency and quality. Dispensing devices also enable the creation of sleek, unobtrusive heating elements that seamlessly integrate functional performance with aesthetic appeal.

Automotive Glass and Electronic Sensors

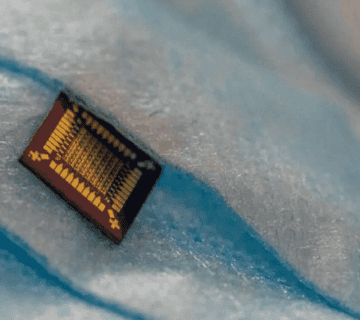

Dispensing technology is equally critical in the integration of electronic sensors into automotive glass, which significantly enhances safety and user comfort. Examples include rain sensors that detect raindrops on windshields to activate automatic wipers, light sensors that adjust headlights based on ambient light levels, and defrost systems that rapidly clear frost and condensation on rear windows.

Dispensing devices simplify the precise application of conductive circuits and pathways needed for these sensors. By ensuring consistency and repeatability, this technology guarantees the reliability of these systems, which are crucial for improving visibility and safety under various driving conditions.

The Transformative Power of Dispensing Technology in Automotive

From car windows to dashboards, seat belts to sensors, dispensing technology has become an indispensable tool across the automotive sector. Elements like the black stripes on automotive glass exemplify how dispensing devices enable seamless integration of functional and aesthetic features. The addition of electronic sensors and conductive materials into vehicle components reflects the broader impact of this technology in enhancing safety, comfort, and efficiency.

The precision, speed, and flexibility of dispensing technology optimize production processes, providing substantial benefits for both manufacturers and end-users. As the automotive and electronics industries continue to converge, dispensing technology will remain a cornerstone of innovation, driving smarter and more efficient solutions for next-generation vehicles.

Building Tomorrow with Beespenser

Dispensing technology is revolutionizing manufacturing processes, paving the way for a smarter and more sustainable future. At Beespenser, we are proud to contribute to this transformation through precision, flexibility, and innovative applications. By partnering with our clients, we aim to shape the future of automotive manufacturing and deliver solutions that redefine what’s possible.