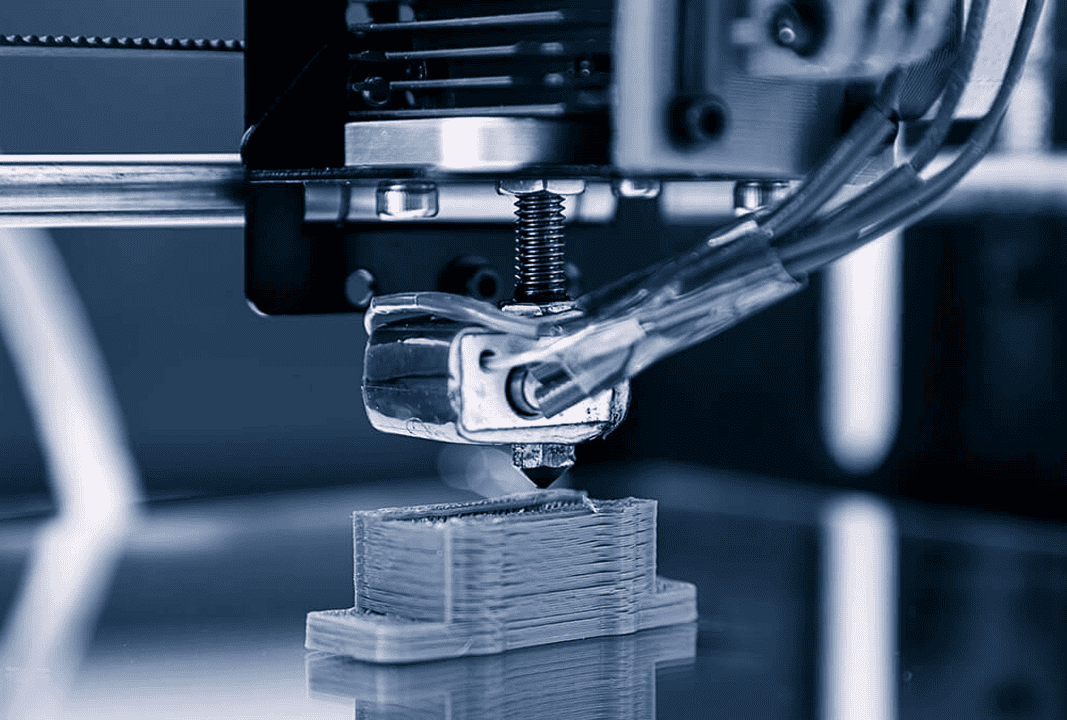

What is Additive Manufacturing?

Additive manufacturing (AM), commonly known as 3D printing, is a transformative approach to creating objects layer by layer. In the field of electronics prototyping, AM allows designers and engineers to bypass traditional manufacturing methods, enabling faster and more efficient production of complex components.

Why Additive Manufacturing is a Game-Changer for Electronics

1. Speed and Efficiency

Additive manufacturing accelerates the prototyping process by eliminating the need for molds, tooling, or assembly lines. Engineers can create functional prototypes within hours instead of weeks. This agility is especially crucial for industries such as healthcare, consumer electronics, and IoT, where time-to-market is a competitive advantage.

2. Cost Reduction

Traditional manufacturing often requires high upfront costs for molds and tooling. With AM, those expenses are eliminated, allowing businesses to allocate resources more effectively. This is particularly advantageous for startups and small businesses, enabling them to compete in markets traditionally dominated by large corporations.

3. Design Freedom

AM enables the production of intricate designs and custom components that are difficult or impossible to achieve using conventional techniques. This flexibility encourages innovation and opens the door for next-generation electronic devices, such as lightweight, flexible wearables and compact medical devices.

4. Material Efficiency

Unlike subtractive manufacturing, which wastes significant material during the production process, AM uses only the exact amount of material required. This not only reduces costs but also aligns with sustainability goals by minimizing waste.

Applications of Additive Manufacturing in Electronics

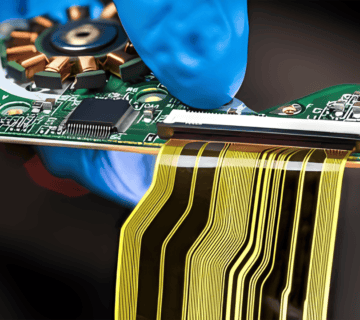

Wearable Devices

Additive manufacturing facilitates the creation of flexible, lightweight circuits that seamlessly integrate with wearable technologies. These advancements are pivotal in developing fitness trackers, smartwatches, and health-monitoring patches.

Medical Devices

In healthcare, AM is used to produce patient-specific medical devices, such as biocompatible implants and precision sensors. The ability to rapidly prototype and iterate designs ensures faster development cycles and better outcomes for patients.

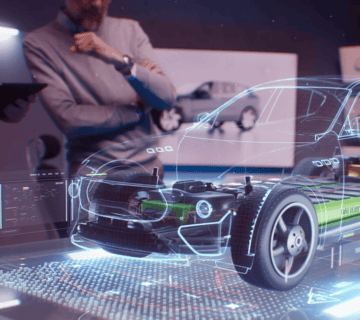

Consumer Electronics

AM enables the creation of innovative consumer electronics, such as foldable screens and customized device components. This allows manufacturers to offer unique features tailored to customer preferences, enhancing user satisfaction.

R&D and Innovation Labs

Additive manufacturing is a staple in research and development settings. Its versatility supports the exploration of novel materials, new circuit designs, and experimental applications, pushing the boundaries of what’s possible in electronics.

Sustainability Through Additive Manufacturing

As global industries aim for greener solutions, additive manufacturing stands out as an environmentally friendly option. Its precision reduces material waste, and the ability to produce components locally decreases transportation emissions. Companies embracing AM can achieve their sustainability goals without compromising on quality or innovation.

Challenges and the Future of Additive Manufacturing

While AM offers numerous advantages, it also faces challenges. For example, the limited availability of conductive materials for electronic components can be a barrier. Additionally, achieving the same level of reliability as traditional methods requires further advancements in material science and manufacturing processes.

However, ongoing research and development are steadily overcoming these hurdles. Innovations in conductive inks, multi-material printing, and high-resolution techniques are shaping the future of AM in electronics.

The Beespenser Advantage

At Beespenser, we integrate the power of additive manufacturing into our cutting-edge devices, offering unparalleled speed, flexibility, and sustainability. Whether you’re developing the next breakthrough in wearable technology or advancing medical device innovation, our solutions empower you to prototype smarter and faster.