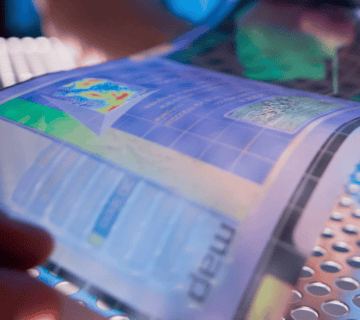

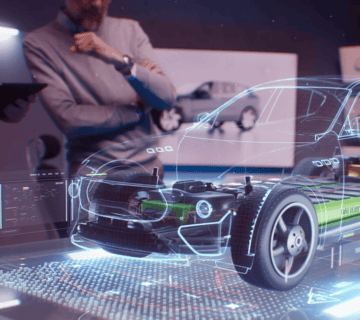

In a world where technology constantly evolves, printed electronics stand out as a revolutionary innovation. Imagine electronics as flexible as fabric, lightweight yet powerful, seamlessly integrated into everyday objects. This exciting field leverages conductive inks to “print” electronic circuits on various surfaces like plastic, paper, or even textiles. The result? New possibilities in areas such as IoT, healthcare, wearable technology, and renewable energy.

With applications ranging from flexible displays to solar panels, printed electronics are paving the way for smarter, more sustainable solutions.

The Advantages Over Traditional Etching

Traditional circuit production often relies on etching, a process that involves the use of harsh chemicals to carve out circuits. While effective, it poses environmental and cost challenges. Printed electronics, on the other hand, offer a cleaner, more efficient alternative.

Key Benefits:

- Eco-Friendly Technology 🌱

Printed electronics eliminate the need for toxic chemicals, significantly reducing environmental impact. - Cost-Effective and Efficient 💸

Direct printing processes are faster and more economical, making them ideal for high-volume production of flexible and customized designs.

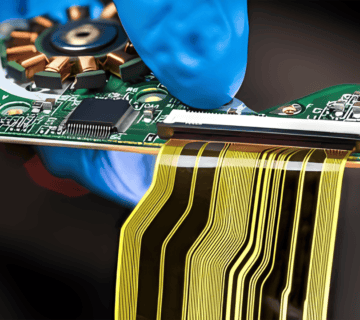

The Role of Conductive Inks in Innovation

At Beespenser, we are dedicated to advancing the potential of printed electronics through innovative conductive inks. These specialized inks allow electronic components to adhere seamlessly to various surfaces, enabling the creation of cutting-edge gadgets such as wearables, IoT devices, and bendable screens.

Types of Inks and Their Functions:

- Conductive Inks: Facilitate electrical flow.

- Dielectric Inks: Act as insulating layers to separate conductive parts.

- Semiconductive Inks: Essential for creating transistors and other components.

- Resistive Inks: Help control electrical resistance in circuits.

By selecting the right ink blend, each device can achieve peak performance—customized to meet the specific demands of the application.

The Science Behind Ink Development

Creating the perfect ink formulation is both an art and a science. Factors like particle size, shape, and the inclusion of binders and surfactants are meticulously balanced to ensure optimal performance.

The Recipe for Success:

- Particle Size and Shape: Smaller, uniform particles ensure smoother and more precise lines.

- Binders: Enhance durability, especially important for wearables and devices exposed to regular use.

- Surfactants: Ensure even ink distribution, improving reliability and consistency.

This level of precision ensures that printed electronics are not only functional but also durable and adaptable.

Practical Applications and Considerations

The choice of ink plays a critical role in the success of printed electronics. For instance:

- Silver Inks: Deliver exceptional conductivity, ideal for high-performance circuits.

- Carbon Inks: Offer flexibility and durability, perfect for wearable devices.

However, the wrong ink choice can lead to issues like reduced conductivity, peeling, or short lifespans. At Beespenser, we focus on tailoring ink solutions to suit the unique requirements of each application, ensuring reliability and long-term performance.

Dielectric Inks: The Unsung Heroes of Flexibility

Dielectric inks are indispensable for creating flexible, multi-layer circuit boards. Acting as insulating layers, they prevent short circuits and allow for the development of complex designs. With variants designed for high-temperature stability or enhanced flexibility, dielectric inks are a cornerstone of modern printed electronics, particularly in wearables and IoT devices.

Printed electronics are transforming the way we integrate technology into our lives, offering sustainable, cost-effective, and innovative solutions. At Beespenser, we are committed to advancing this field by perfecting the science of conductive inks. Whether you’re developing wearables, IoT devices, or flexible displays, our tailored ink formulations provide the foundation for next-generation technology.

Stay connected for more insights into the exciting world of printed electronics. Together, we can shape a smarter future.