Flexible Substrates: The Foundation of Flexible Electronics

Flexible substrates form the backbone of electronic circuits. Common materials include plastic films, polyimide, and thin glass, which allow devices to bend and stretch, enabling innovative form factors previously unimaginable.

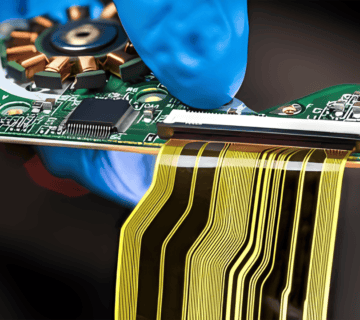

Rigid PCBs vs. Flexible PCBs

Flexible PCBs offer significant advantages over rigid ones, providing enhanced durability and adaptability for modern applications.

Semiconductors: The Heart of Flexible Electronics

Organic semiconductors are essential for creating active components in flexible electronics, such as transistors and diodes. These materials can be processed at low temperatures, making them ideal for flexible substrates. This combination enables lightweight, flexible devices with complex functionalities.

Conductive Inks: Printing the Future

Conductive inks, containing materials like silver, copper, or carbon nanotubes, are used to print electronic circuits onto flexible substrates. This printing process, similar to traditional inkjet or screen printing, is cost-effective for large-scale production and perfect for creating intricate circuits on flexible surfaces.

Applications of Flexible Electronics

Wearable Devices

Flexible electronics lead the wearable technology revolution. Devices like smartwatches, fitness trackers, and health monitoring patches benefit greatly from flexibility, adapting to body contours and movements for enhanced comfort and functionality.

Healthcare

In healthcare, flexible electronics enable advanced diagnostic and therapeutic devices. Flexible sensors can monitor vital signs, wound healing, or drug delivery, offering non-invasive and continuous monitoring options.

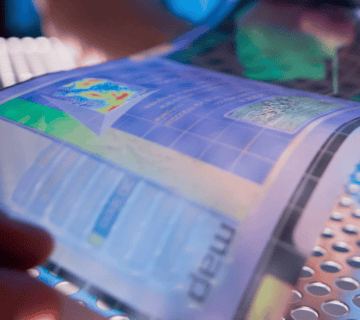

Consumer Electronics

The consumer electronics industry is experiencing a wave of innovation powered by flexible electronics. Foldable smartphones, rollable displays, and lightweight, flexible solar panels are just a few examples. These advancements not only enhance user experiences but also introduce new functionalities.

Industrial Applications

In industrial environments, flexible sensors and circuits are integrated into smart textiles, robotic skins, and structural health monitoring systems. These applications improve efficiency, safety, and real-time data collection across various sectors.

Advantages of Flexible Electronics

Design Freedom

Flexible electronics offer unparalleled design freedom, enabling innovative shapes and configurations that traditional rigid electronics cannot achieve. This opens up new possibilities for product design and user interaction.

Durability

The ability to withstand bending, folding, and stretching makes flexible electronics more durable in many applications. This durability results in longer device lifespans and reduced maintenance costs.

Lightweight and Thin

Flexible electronic devices are often lighter and thinner than rigid ones, making them more portable and easier to integrate into various environments and products.

Cost-Effective Manufacturing

Techniques like roll-to-roll printing and low-temperature processing make mass production of flexible electronics more cost-effective than traditional silicon-based electronics.

Challenges and Future Directions

Despite their high potential, flexible electronics face challenges. Durability under repeated mechanical stress needs improvement, and the performance of flexible components like transistors and batteries must match or exceed rigid counterparts.

Research is focused on enhancing material properties, refining production techniques, and expanding application possibilities. Advances in nanotechnology, material science, and printing technologies are expected to drive significant progress in this field.

Flexible electronics represent a groundbreaking leap in technology, offering a wide range of applications across industries. As the technology evolves, it promises the creation of more innovative, durable, and versatile electronic devices, reshaping how we interact with and use technology in the future.