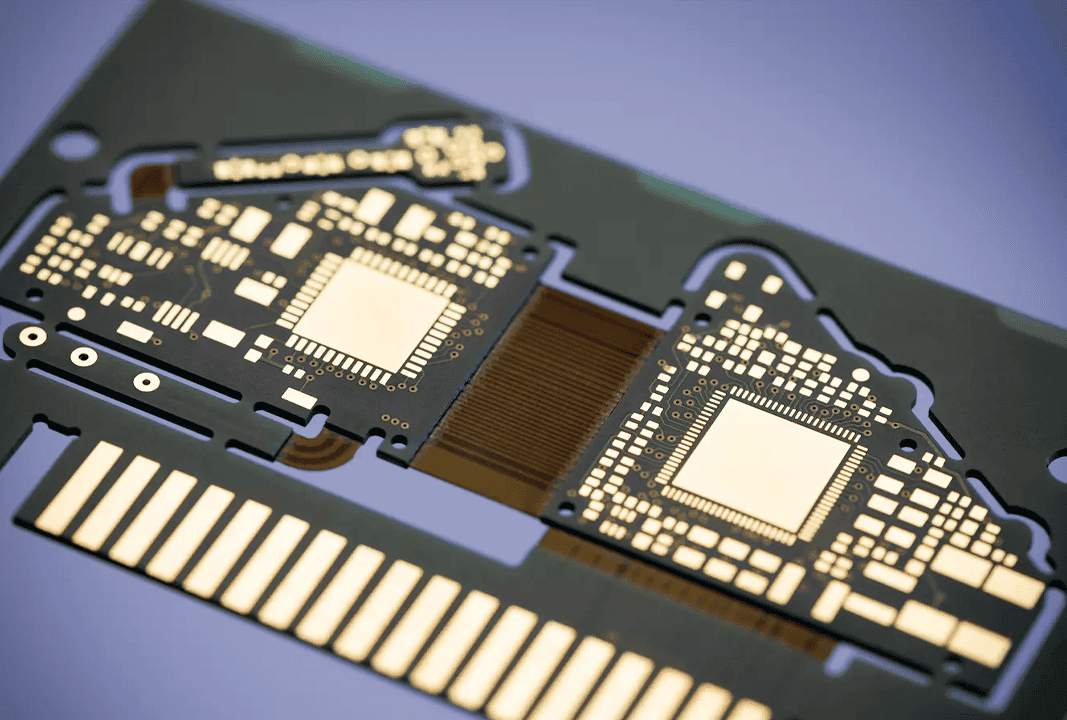

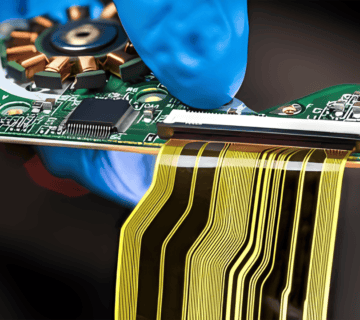

What Are Flexible PCBs?

Flexible Printed Circuit Boards (PCBs) are an innovative type of circuit board designed to bend and conform to different shapes. Unlike traditional rigid PCBs, flexible PCBs are made from materials like polyimide or polyester film, offering both durability and adaptability. These qualities make them indispensable in industries ranging from healthcare to consumer electronics.

Why Flexible PCBs Are Revolutionizing Electronics

1. Design Versatility

Flexible PCBs enable engineers to create devices with unconventional shapes and sizes. This versatility is essential for wearables, foldable devices, and other advanced electronics that demand intricate designs and compact form factors.

2. Lightweight and Space-Saving

The thin and lightweight nature of flexible PCBs allows them to reduce the overall weight of devices. They are particularly useful in applications where space is limited, such as in medical implants or aerospace equipment.

3. Enhanced Durability

Flexible PCBs are designed to withstand vibrations, bending, and mechanical stresses better than their rigid counterparts. This makes them ideal for environments with extreme conditions or devices subject to frequent movement.

4. Cost-Effective Manufacturing

By combining multiple components into a single flexible PCB, manufacturers can streamline assembly processes and reduce production costs. Roll-to-roll manufacturing techniques further enhance scalability and cost efficiency.

Applications of Flexible PCBs

Wearable Technology

Flexible PCBs are the backbone of wearable devices like smartwatches, fitness trackers, and health-monitoring patches. Their ability to conform to the body ensures both comfort and reliability.

Medical Devices

In healthcare, flexible PCBs enable the creation of biocompatible, minimally invasive medical devices such as pacemakers, hearing aids, and diagnostic sensors.

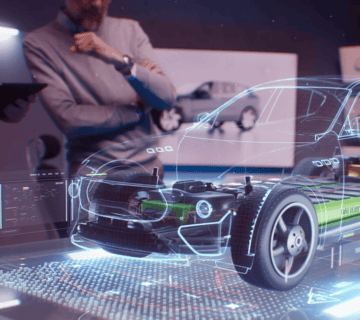

Automotive Electronics

Modern vehicles rely on flexible PCBs for advanced features like adaptive headlights, dashboard displays, and engine monitoring systems. Their resilience ensures reliable performance in harsh driving conditions.

IoT and Smart Devices

Flexible PCBs play a critical role in IoT devices, enabling compact designs and efficient connectivity. From smart home sensors to industrial IoT systems, their adaptability is unmatched.

Challenges in Flexible PCB Manufacturing

While flexible PCBs offer numerous advantages, their production is not without challenges. Ensuring high reliability during repeated bending cycles, managing heat dissipation, and achieving consistent performance across complex designs are key areas of focus.

Advancements in materials and manufacturing techniques, such as the use of conductive inks and high-resolution additive printing, are helping to address these challenges and expand the capabilities of flexible PCBs.

The Beespenser Edge: Redefining Flexible PCB Prototyping

Beespenser’s cutting-edge technology simplifies the prototyping of flexible PCBs, making it faster and more accessible. By combining advanced additive manufacturing with precision engineering, we empower innovators to design, print, and test flexible circuits in-house.

Whether you’re developing wearables, medical devices, or IoT solutions, Beespenser provides the tools you need to stay ahead in a rapidly evolving market.

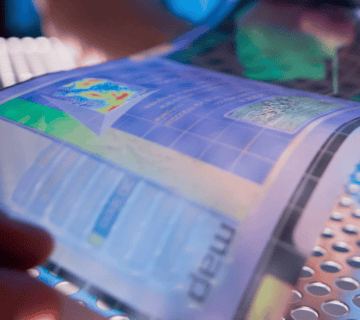

Discover the Future of Electronics Design

Flexible PCBs are revolutionizing how we think about electronics, offering unparalleled design freedom, durability, and efficiency. With Beespenser, you can unlock the potential of flexible electronics and bring your ideas to life faster than ever.