Exploring New Frontiers

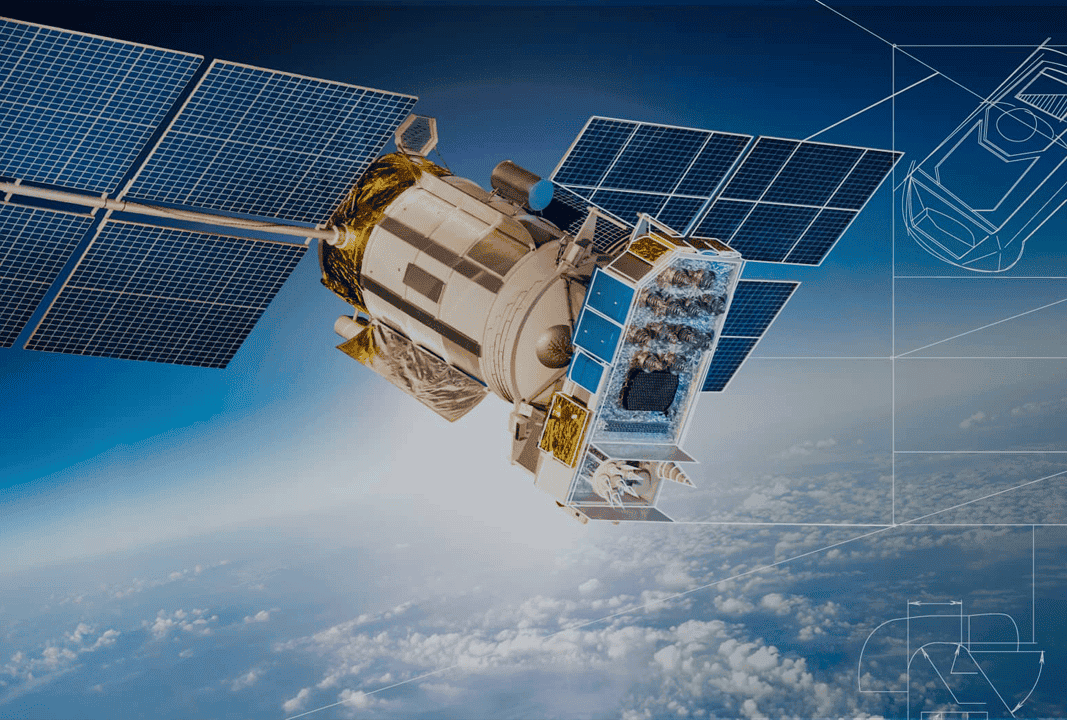

Electronics serve as the technological backbone of modern space missions, powering critical systems such as spacecraft navigation, environmental monitoring, and communication. However, relying on Earth-based manufacturing for electronic components imposes several constraints, including high logistical costs, long lead times, and limited adaptability to unexpected challenges.

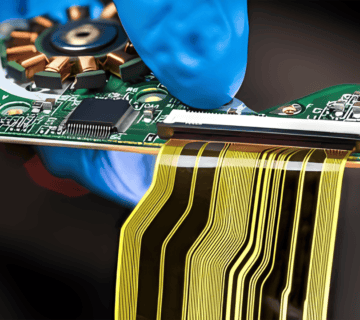

As humanity prepares for long-duration and autonomous missions to destinations like the Moon, Mars, and beyond, a new approach to electronics production and deployment is essential. The development of compact and versatile PCB (Printed Circuit Board) printers offers an innovative solution to these challenges. By enabling on-demand manufacturing of electronic components directly in space, these technologies enhance mission sustainability and reduce dependence on Earth-based supply chains.

Challenges of Space-Based Electronics Production

Microgravity Effects

Traditional manufacturing processes designed for Earth face significant obstacles in microgravity environments. The absence of gravitational forces affects fluid dynamics, material deposition, and assembly techniques, requiring new methods tailored for low-gravity conditions. For example, traditional soldering techniques rely on gravity for uniform material distribution. Advancements in electrohydrodynamic (EHD) printing have shown promise in addressing these challenges. EHD printing utilizes electric fields to control material placement, enabling precise circuit production in microgravity conditions (NASA, 2003).

Material Constraints

Transporting raw materials from Earth to space is highly cost-prohibitive, with payload expenses often exceeding $10,000 per kilogram.

This limitation necessitates resource-efficient manufacturing solutions that minimize waste and optimize material usage. In-space recycling technologies, such as converting polymer waste into feedstock for 3D printing, have demonstrated feasibility aboard the International Space Station (Academia.edu, 2022).

Incorporating these advancements into PCB production could significantly reduce reliance on Earth-based supply chains and enhance the sustainability of long-duration missions.

Environmental Factors

The space environment is characterized by extreme conditions, including high radiation levels, temperature fluctuations, and vacuum conditions. These factors can degrade the durability and functionality of electronic components. Radiation exposure, for example, can damage semiconductors, while repeated thermal cycling can lead to material fatigue.

Advanced material science solutions, such as radiation-hardened substrates and thermal coatings, are essential to ensuring the longevity and reliability of space-manufactured electronics (NASA Microgravity Materials Science, 2016).

Equipment Footprint

Spacecraft and habitats have limited room for additional equipment, making compact and multifunctional tools essential for onboard manufacturing. Research underscores the importance of integrating multiple capabilities into a single system to optimize resource efficiency (Springer, 2022). Compact PCB manufacturing devices must meet these constraints while maintaining the capability to produce high-quality, reliable circuits for a wide range of applications.

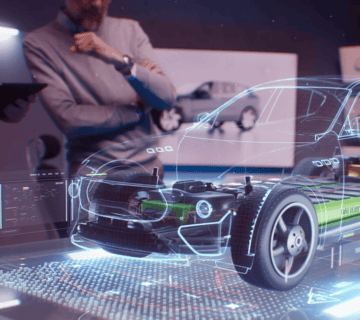

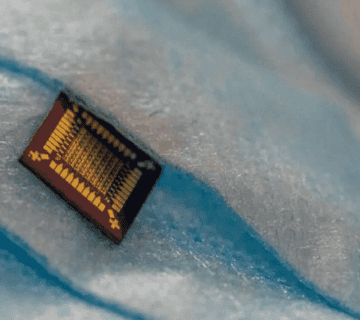

The Role of Beespenser

Beespenser’s Monobee device exemplifies the innovative solutions needed for space-based electronics manufacturing. With its compact and portable design, Monobee enables the rapid and efficient production of electronic components in space. By addressing challenges such as material efficiency, environmental durability, and limited equipment footprint, Monobee enhances mission flexibility and lays the foundation for Earth-independent operations. This cutting-edge technology marks a significant step forward in redefining electronic manufacturing processes for long-duration space missions.

A New Era of Exploration

The future of space exploration depends on sustainable and adaptable technologies. Compact PCB printers, such as Beespenser’s Monobee, represent a pivotal advancement in meeting the demands of long-duration missions. By enabling in-space manufacturing of critical electronic components, these innovations reduce dependency on Earth and open new frontiers in autonomous space exploration.

Get ready to explore the next era of electronics manufacturing in space with Beespenser. Together, let’s shape the future of space exploration!