What is Conductive Ink?

Conductive ink is a specialized ink designed to conduct electricity, made possible by the inclusion of conductive materials such as silver, copper, or carbon. This technology is used in various printing processes to create electronic circuits and components. Due to its ability to support flexible and lightweight electronic designs, conductive ink has become an essential tool for rapid prototyping and cost-effective circuit manufacturing. Its development was driven by the demand for more efficient, adaptable, and environmentally friendly methods of producing electronic circuits and components.

Where Do We Use Conductive Inks?

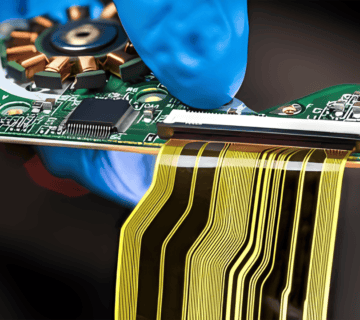

The rise of portable devices, IoT (Internet of Things) technologies, wearable electronics, and flexible displays has positioned conductive inks as a transformative innovation. Traditional printed circuit board (PCB) manufacturing methods are often complex, energy-intensive, and environmentally harmful due to their reliance on toxic chemicals. Moreover, the rigid surfaces and high-temperature requirements of these methods limit their suitability for modern flexible and lightweight devices.

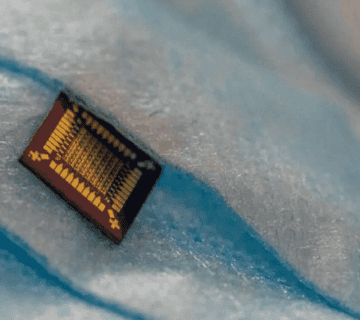

Conductive inks have addressed these challenges, enabling the creation of flexible electronic devices, RFID tags, and NFC technologies. As their applications have grown, the industry has expanded significantly in regions such as the Americas, Europe, China, and Japan, underscoring their global impact.

Devices That Use Conductive Inks

Several devices leverage conductive inks for various applications, including syringe-based inkjet printers, roll-to-roll (R2R) systems, and screen-printing machines. Among these, screen-printing devices stand out for their ability to mass-produce circuits, printing hundreds of complex designs simultaneously.

The advancement of nanotechnology has broadened the material base for conductive inks, introducing options such as metals (silver, gold, and copper), carbon-based nanomaterials, and conductive polymers. These materials have enabled the development of highly conductive, flexible products tailored to a wide array of applications. Moving beyond traditional rigid surfaces, conductive inks are now used in flexible displays, foldable phones, and advanced sensor technologies. Additionally, they create low-resistance conductive paths in solar cells and batteries, contributing to innovations in energy storage solutions.

Advantages of Conductive Ink Technology

The adoption of conductive ink technology offers several advantages over traditional methods of electronic manufacturing:

- Cost Efficiency: Conductive ink manufacturing simplifies circuit production, eliminating the need for complex, energy-intensive processes.

- Eco-Friendliness: Unlike traditional methods, conductive inks reduce waste and rely on fewer harmful chemicals, making them a more sustainable option.

- Rapid Prototyping: Conductive inks accelerate product development cycles, enabling faster market introductions for innovative technologies.

- Flexibility: These inks can be applied not only to flat surfaces but also to curved or flexible materials, expanding their range of applications.

By driving more flexible, innovative, and sustainable electronic manufacturing processes, conductive ink technology plays a pivotal role in advancing next-generation technologies.

What is Beespenser’s Aim?

Beespenser is dedicated to shaping the future of electronic manufacturing. Our vision is to become the first company in the world to produce both circuit printing devices and conductive inks. By developing PCB prototyping devices based on additive manufacturing and launching our own silver- and carbon-based conductive inks, we aim to revolutionize the electronics industry.

Shape the Future of Electronics with Beespenser

As technology evolves, Beespenser continues to lead the way in delivering innovative solutions for modern electronics. Through precision, adaptability, and a commitment to sustainability, we strive to empower our partners to create groundbreaking technologies that redefine what’s possible.